Proper chimney function in your commercial HVAC system guarantees safe removal of combustion byproducts while maintaining ideal energy efficiency. You'll need to maintain consistent negative pressure between -0.02 and -0.08 inches water column for effective draft control. Regular inspections and maintenance are vital, as ventilation blockages and improper sizing can lead to system failures and safety hazards. Your chimney's performance directly impacts HVAC efficiency, potentially affecting energy consumption by 15-20%. Compliance with NFPA 211 standards and local regulations is essential for safe operation. Understanding the intricate relationship between chimney design and HVAC performance will reveal significant operational benefits.

Understanding Commercial Chimney Basics

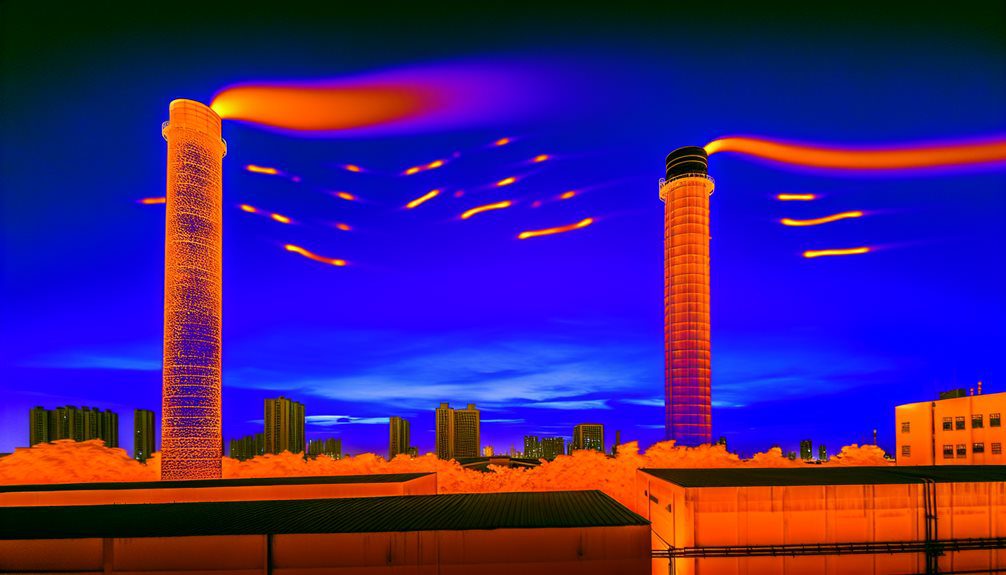

Commercial chimneys serve as vital components in HVAC systems, facilitating the safe removal of combustion byproducts and maintaining ideal system efficiency. When you're evaluating your building's HVAC infrastructure, you'll need to understand the fundamental chimney design factors that affect your system's performance.

Your commercial chimney must meet specific performance metrics, including draft pressure, flow capacity, and temperature resistance. These factors directly impact your system's ability to maintain proper airflow and prevent dangerous backdrafting. You'll find that chimney height, diameter, and material composition work together to create optimal venting conditions.

As a facility manager or building owner, you're responsible for ensuring your chimney system maintains consistent negative pressure. This means understanding how factors like wind loading, atmospheric conditions, and stack effect influence your chimney's operation. You'll need to examine the relationship between your HVAC equipment's BTU rating and your chimney's capacity, as proper sizing is essential for system efficiency. Additionally, you'll want to monitor condensation levels and flue gas temperatures to prevent corrosion and maintain long-term structural integrity of your venting system.

Common Venting System Problems

The most prevalent venting system problems stem from inadequate draft, incorrect sizing, and material deterioration. You'll find that ventilation blockages often develop from debris accumulation, while flue obstructions can result from nesting birds or deteriorating masonry. These issues frequently lead to dangerous exhaust backflow into your building's occupied spaces.

Draft issues typically arise from improper sizing of the chimney system, where the diameter or height doesn't match your HVAC equipment's specifications. When you're experiencing temperature fluctuations or airflow restrictions, it's often due to system leaks in the flue liner or connections. You'll need to address these promptly to maintain proper ventilation.

Maintenance neglect accelerates chimney deterioration, especially in areas where acidic condensate can damage the flue liner. You'll notice that commercial systems are particularly susceptible to these problems due to their higher usage rates and complex configurations. It's essential to implement regular inspections to identify potential issues before they compromise your system's efficiency or safety. When you spot signs of wear, such as crumbling mortar or rust stains, you're likely dealing with advanced deterioration that requires immediate professional attention. Regular inspections are crucial for maintaining chimney integrity and preventing more severe damage.

Safety Regulations and Code Requirements

Building code compliance links directly to the ventilation issues discussed above, with specific regulations governing every aspect of commercial HVAC chimney installations. You'll need to guarantee your system meets both local and national safety compliance requirements, including NFPA 211 standards and International Mechanical Code specifications.

When you're maintaining your commercial HVAC system, you must follow regulatory standards for chimney clearances, which typically require a minimum of 2 inches from combustible materials and proper firestopping at floor penetrations. You'll find that code requirements also dictate specific materials for chimney liner construction, with most jurisdictions mandating UL-listed components.

You're required to implement regular inspection schedules that align with ASHRAE 62.1 guidelines, and you'll need to maintain detailed documentation of all safety checks and maintenance procedures. Your ventilation system must incorporate proper draft controls, and you're obligated to install carbon monoxide detectors in accordance with current building codes. Remember that non-compliance can result in hefty fines and potential system shutdown, so it's essential to stay current with updated regulatory requirements through ongoing professional certification and training.

Maintaining Optimal Draft Control

Within commercial HVAC systems, maintaining proper draft control requires precise calibration of pressure differentials and airflow dynamics. You'll need to implement consistent draft measurement techniques to monitor the chimney's performance and guarantee peak operation throughout varying environmental conditions. When you regularly assess draft patterns, you're joining other HVAC professionals who understand the critical nature of maintaining stable negative pressure.

To enhance your system's draft control, you'll want to employ proven airflow enhancement methods, including differential pressure monitoring and velocity measurements at key points. You can install draft gauges at strategic locations to track real-time performance and make necessary adjustments. It's essential that you maintain draft readings within manufacturer-specified ranges, typically between -0.02 and -0.08 inches water column for most commercial applications.

Chimney Liners and Material Options

When selecting chimney liners for commercial HVAC systems, you'll encounter three primary material options: stainless steel, aluminum, and clay or ceramic composites. Your material selection should directly align with the system's operating temperature, fuel type, and condensate exposure levels. The choice between these materials requires careful analysis of cost-efficiency ratios, local code requirements, and expected service life under your specific operating conditions.

Common Liner Material Types

Commercial HVAC chimney systems rely on specific liner materials to maintain safety, efficiency, and code compliance. You'll commonly encounter three primary chimney liner materials in commercial applications: stainless steel, aluminum, and clay tile. Each material serves distinct purposes and offers unique advantages for your system's requirements.

Stainless steel liners are your most versatile option, featuring high heat resistance and durability. You'll find them in both rigid and flexible formats, with installation techniques varying based on your chimney's configuration. For moderate-temperature applications, aluminum liners provide a cost-effective solution, though they're limited to gas appliances and lower temperature ranges.

Clay tile liners, while traditional, remain popular in masonry chimneys. You'll need to take into account their installation carefully, as they require proper sizing and professional placement. When selecting your liner material, focus on factors like flue gas temperature, fuel type, and local building codes. For instance, high-efficiency condensing systems typically require acid-resistant stainless steel liners, while standard efficiency units might accommodate aluminum options. Additionally, it's crucial to consider masonry restoration services to address any potential chimney issues before installation. Remember that proper installation techniques greatly influence your system's longevity and performance, regardless of the material chosen.

Material Selection Criteria

Selecting appropriate chimney liner materials demands a systematic evaluation of multiple technical parameters. You'll need to assess flue gas temperature ranges, condensate exposure levels, and the specific fuel types your commercial HVAC system utilizes. These factors directly influence your material selection process and subsequent installation techniques.

When you're evaluating chimney materials, you'll want to contemplate their resistance to thermal shock, corrosion tolerance, and structural integrity under varying operating conditions. For instance, if you're dealing with high-temperature applications above 1000°F, you'll find that stainless steel alloys offer superior performance compared to aluminum alternatives. You'll also need to factor in the liner's compatibility with existing masonry and its ability to accommodate thermal expansion.

Your selection criteria should include an analysis of maintenance requirements, expected service life, and compliance with local building codes. It's essential that you reflect on the seismic requirements of your region and the liner's ability to maintain proper draft characteristics. Remember, your choice of materials will greatly impact both the initial installation costs and long-term operational efficiency of your commercial HVAC system.

Preventing Carbon Monoxide Hazards

Protecting your commercial HVAC system from carbon monoxide hazards requires implementing a thorough safety protocol that includes scheduled inspections and certified testing procedures. You'll need to install advanced CO detection systems with automated alerts and emergency shutdown capabilities to guarantee immediate response to dangerous gas levels. Your ventilation maintenance protocols must incorporate systematic cleaning schedules, airflow monitoring, and professional verification of proper exhaust functions to prevent CO accumulation in occupied spaces.

Regular Inspection and Testing

Safety protocols demand regular chimney inspections in commercial HVAC systems to prevent carbon monoxide infiltration. You'll need to implement thorough chimney assessment techniques that include visual examinations, pressure testing, and internal camera inspections. Following inspection frequency guidelines, you should schedule Level 1 inspections annually and Level 2 inspections after system modifications or suspected damage.

Your inspection routine must cover critical components including the flue liner, chimney cap, crown, and connecting ducts. You'll want to document visible deterioration, blockages, or structural issues that could compromise proper ventilation. During testing, you'll measure draft pressure, conduct smoke tests, and verify that exhaust gases aren't being redirected into the building.

Make sure you're adhering to NFPA 211 standards when performing these inspections. You'll need to maintain detailed records of findings, repairs, and maintenance actions. When you discover issues, don't delay addressing them – even minor problems can escalate into major safety concerns. Remember that your building's occupants rely on your diligence in maintaining these essential safety systems, so establish a reliable inspection schedule and stick to it.

Emergency Detection Systems Installation

To maintain ideal safety standards, you'll need to integrate carbon monoxide detection systems with your commercial HVAC chimney infrastructure. Your detection system's placement requires strategic positioning at multiple levels throughout your building, ensuring thorough coverage of potential gas accumulation zones.

You'll want to install primary sensors near chimney connection points, mechanical rooms, and areas where exhaust gases might concentrate. The emergency alarms should connect directly to your building's central monitoring system, enabling immediate response protocols when CO levels exceed safe thresholds. System integration with your HVAC controls allows for automatic shutdown procedures if dangerous conditions arise.

Your detection network should include both audible and visual alerts, with backup power sources ensuring continuous monitoring even during power failures. When you're selecting sensors, opt for devices that offer digital readouts and data logging capabilities, allowing you to track historical patterns and identify potential system degradation before it becomes critical. Remember to calibrate your sensors according to manufacturer specifications and local building codes. This systematic approach to emergency detection provides your facility with thorough protection while meeting regulatory compliance requirements for commercial HVAC operations.

Proper Ventilation Maintenance Protocols

Building upon your detection systems, regular ventilation maintenance forms the backbone of carbon monoxide prevention in commercial HVAC operations. You'll need to implement systematic ventilation system maintenance protocols that align with industry standards and local regulations.

Schedule quarterly inspections of your chimney's internal components, including flue liners, dampers, and combustion chambers. You're responsible for maintaining proper draft conditions, which you can verify through pressure differential testing. Your maintenance team should document all findings and immediately address any irregularities in airflow patterns.

Your chimney cleaning protocols must include:

- Monthly debris removal from exhaust pathways

- Bi-annual inspection of weather caps and spark arrestors

- Quarterly assessment of mortar joints and crown seals

- Semi-annual cleaning of heat exchangers

- Annual thermographic scanning of vent walls

You'll want to coordinate these maintenance activities with your building's operational schedule to minimize disruption. Remember to maintain detailed logs of all cleaning procedures, including dates, findings, and corrective actions taken. Your team's consistent adherence to these protocols guarantees peak system performance and protects your building's occupants from potential carbon monoxide exposure.

Energy Efficiency Impact

Proper chimney function ties directly into the overall energy efficiency of commercial HVAC systems. When your chimney operates at peak performance, you'll notice significant improvements in energy recovery and system enhancement. A well-maintained chimney reduces the workload on your HVAC equipment, resulting in lower energy consumption and operating costs.

You'll find that efficient chimney draft creates a natural flow that supports your building's thermal balance. By maintaining proper draft conditions, you're enabling your HVAC system to work within its designed parameters, reducing unnecessary cycling and energy waste. The stack effect in your chimney plays a vital role in heat distribution and air exchange efficiency.

Monitor your system's performance metrics to guarantee ideal chimney function. You can achieve up to 15-20% better energy efficiency when your chimney system integrates seamlessly with your HVAC operations. Consider installing draft regulators and sensors to maintain consistent airflow patterns. These components help you maximize energy recovery potential while minimizing heat loss through the chimney structure. Regular assessment of draft patterns and temperature differentials will help you identify opportunities for system enhancement and energy savings.

Modern HVAC Venting Challenges

Modern commercial HVAC systems require you to manage complex building exhaust designs that accommodate multiple air streams, varying equipment loads, and intricate ductwork configurations. You'll find that pressure differentials between building zones present significant safety challenges, particularly in maintaining proper backdraft prevention and ensuring consistent exhaust flow patterns. Your building's exhaust system must integrate sophisticated pressure management controls to prevent harmful gas migration and maintain safe indoor air quality while meeting strict building codes.

Building Exhaust Design Complexities

Professional engineers grapple with increasingly complex exhaust requirements in contemporary commercial HVAC systems. When you're designing building exhaust systems, you'll need to take into account multiple variables that affect exhaust flow, including stack effect, wind pressure, and atmospheric conditions. Your calculations must account for both positive and negative pressure zones throughout the building envelope.

You'll find that proper duct sizing becomes critical as systems grow more sophisticated. Your design must balance factors like flow velocity, pressure drop, and system efficiency while meeting strict building codes and environmental regulations. Modern buildings often require specialized solutions for various exhaust streams – from kitchen ventilation to laboratory fume hoods – each with unique temperature and contamination considerations.

As a building systems professional, you're responsible for integrating these exhaust components with makeup air systems and building pressurization controls. You'll need to evaluate potential cross-contamination risks, implement fail-safes, and guarantee your design maintains proper air balance during all operating conditions. Your exhaust system design must also accommodate future modifications and equipment upgrades while maintaining peak performance throughout the building's lifecycle.

Pressure Management Safety Issues

When managing pressure differentials in commercial HVAC venting systems, you'll encounter critical safety challenges that demand rigorous monitoring and control protocols. You'll need to maintain precise negative pressure relationships between connected spaces while preventing dangerous backdrafting conditions that can compromise occupant safety.

As part of your pressure management strategy, you'll want to implement continuous monitoring systems that track pressure differentials across key zones. You'll find that proper safety protocols require maintaining specific pressure gradients between -0.02 and -0.05 inches water column (WC) in most commercial applications. These measurements help you prevent both excessive negative pressure that could impede door operation and insufficient negative pressure that might allow contaminated air migration.

You'll need to verify your building automation system (BAS) includes fail-safes and automated shutdown sequences for scenarios where pressure imbalances exceed predetermined thresholds. It is crucial to integrate pressure sensors with your fire suppression systems and emergency ventilation controls. By following these technical specifications, you're protecting your facility while meeting ASHRAE standards and local building codes that govern pressure management requirements.

Inspection and Maintenance Schedule

Regular maintenance of commercial HVAC chimney systems requires three essential inspection intervals: monthly visual checks, quarterly operational assessments, and annual thorough evaluations. You'll need to maintain a consistent inspection frequency to guarantee peak performance and compliance with safety regulations.

During monthly inspections, you should check for visible damage, debris accumulation, and signs of deterioration around the chimney crown and flashing. Your maintenance checklist must include verifying that all access points remain secure and examining the exterior for structural integrity.

Quarterly assessments call for more detailed examination of draft performance, connection points, and liner conditions. You'll want to test damper functionality and measure exhaust temperatures to identify potential issues before they become critical problems.

Your annual evaluation requires extensive testing of all components, including pressure measurements, thermal imaging scans, and detailed documentation of wear patterns. You'll need to coordinate with certified technicians to perform deep cleaning, replace worn components, and update maintenance records. This thorough inspection helps you maintain building code compliance and extends your system's operational lifespan while preventing unexpected failures.

Upgrading Outdated Chimney Systems

Outdated commercial HVAC chimney systems can drag down your building's overall energy efficiency and pose significant safety risks. When you're considering chimney upgrades, you'll need to evaluate several critical components to guarantee ideal system efficiency and compliance with current building codes.

Start by reviewing your existing chimney liner. You'll want to upgrade from clay or unlined masonry to modern stainless steel liners, which offer superior corrosion resistance and improved draft performance. Consider installing a chimney fan system to maintain consistent airflow and prevent backdrafting, especially if you've modified your HVAC equipment over the years.

Don't overlook the importance of proper sizing when planning your upgrades. Your new chimney system must match your HVAC equipment's specifications to prevent condensation issues and guarantee efficient operation. You'll need to calculate the correct cross-sectional area and height based on your equipment's BTU rating and exhaust requirements.

Installing monitoring systems with your upgrades will help you track performance metrics and detect potential issues before they become major problems. These systems can measure draft pressure, flue gas temperature, and carbon monoxide levels, guaranteeing your upgraded chimney operates safely and efficiently. Regular maintenance, including chimney repair, is essential to ensure the longevity and functionality of your upgraded systems.

Frequently Asked Questions

How Long Does a Commercial Chimney System Typically Last Before Needing Replacement?

Your commercial chimney system's lifespan typically ranges from 15-50 years, but several chimney lifespan factors influence this timeline. You'll find that regular maintenance schedules, including annual inspections and cleanings, can extend its life considerably. Your system's longevity depends on factors like material quality, weather exposure, usage intensity, and local climate conditions. You should plan for replacement when you notice deterioration of flue liners, persistent moisture issues, or structural concerns.

Can Multiple HVAC Units Share the Same Chimney System Legally?

You can connect multiple HVAC units to a shared chimney system, but you'll need to guarantee strict code compliance and proper chamber design. The key factors you must consider include the total BTU load, flue gas volume, and adequate sizing of the common vent. Your system's design must prevent backdrafting and maintain proper draft for each unit. Remember, local building codes may have specific requirements, so you'll want to consult with a certified HVAC engineer before implementation.

What Are the Cost Differences Between Masonry and Factory-Built Commercial Chimneys?

You'll find that masonry chimneys typically cost 30-40% more upfront than factory-built systems due to labor-intensive installation and materials. However, masonry benefits include longer lifespan (50+ years) and better durability against extreme weather. Factory-built efficiency shines through faster installation, lower initial costs, and lightweight materials. When you're calculating total investment, remember to factor in maintenance costs – masonry requires less frequent repairs but more expensive fixes when needed.

Do Insurance Rates Change Based on Chimney System Type and Age?

Yes, you'll find that insurance premiums typically vary based on your chimney system's type and age. Modern factory-built systems often qualify for lower rates due to their standardized safety features and documented compliance. Your masonry chimney may lead to higher premiums, especially if it's older than 25 years. Regular chimney inspections can help reduce your rates, as they demonstrate proactive maintenance and risk management to insurance providers.

Are There Tax Incentives for Upgrading Commercial Chimney Systems to Modern Standards?

You'll find several tax credits available when upgrading your commercial chimney systems, particularly through federal energy efficiency incentives. You can claim up to 10% of costs through the Energy Policy Act, and additional state-specific deductions may apply. Many utility companies also offer rebates when you modernize your ventilation systems. Be sure to consult with a tax professional, as these incentives often require specific energy performance certifications and documentation.