Our Services Include

Tuckpointing

Tuckpointing becomes mandatory when mortar joints have cracked, flaked, or disintegrated due to the abrasive effects of the elements. Although the right material and technique are enough to deliver a water-tight job, Arrow Masonry believes appearance is also a top priority.- Our skilled crews carefully select the proper mortar mix and tools to compliment your existing mortar color and profile. If the cracks, gaps and voids within the mortar joints are left neglected, water will most certainly find its way into the interior causing leaks, damage to drywall, paint and promote mold growth.

Masonry Restoration

Masonry restoration is not only costly but if performed in the wrong manner can be unsightly. Mismatched mortar and incompatible brick replacement will leave undesirable features on your masonry walls for years to come. Arrow Masonry will not only repair the structural deficiencies within your brick, concrete block and stone facades but will do so in a way to enhance its cosmetic appeal. We carefully select the closest brick match to your original not only in color but in texture to insure the integration of the old and new. The best compliment we have received was not seeing the repair at all!

Brick Repair

Penetrating moisture not only weakens the mortar that bonds the bricks together, but it also promotes premature deterioration of the brick. If moisture finds its way into a defect on the brick and freezes, it will cause the brick to spall, deflect or displace. Once this happens, the brick is rendered useless as it offers no structural support to the brick wall. Removing defective bricks will prevent water damage from spreading to the healthy and sound bricks remaining. Arrow Masonry works with a variety of brick suppliers to insure you the closest match to your existing brick when a brick repair is required.

Stone Restoration

Limestone, Renaissance stone, Cultured stone, Sandstone, Terra Cotta are different types of stone facades that Arrow repairs and replaces. Stone is particularly porous and special attention is needed to maintain it. Most often stone becomes discolored or dislodged and Arrow is contacted to clean, patch, reset or replace it. Another common threat to stone facades is de-icing salts. The salts etch and erode the surface of the stone and wear down its integrity. After the stone is properly repaired or replaced, Arrow usually follows up with a waterproofing treatment to slow down the intrusion of the water and chemicals.

Lintel Replacement

Lintels (angle irons), I-Beams and C-Channels with welded plates are all used to bridge openings within masonry walls. They are imperative in carrying the cumulative load of multi-floor heights of masonry. If these crucial steel members corrode and bow, the structural stability of the masonry wall becomes questionable. In addition, all openings should have a proper flashing system installed to divert water out and away from the interior of the opening. Flashing with drip wicks are necessary components to keep steel lintels, C-Channels, and I-Beams from corroding.

Failing lintels are the cause of many City of Chicago violations. Before your masonry building gets a citation or worse, becomes a public hazard with costly liabilities, contact Arrow Masonry. Let Arrow Masonry’s experienced staff offer you a thorough assessment of what your masonry building requires to become watertight and structurally sound.

Chimney Repair

Chimneys are usually the first part of a masonry building to manifest signs of deterioration. This is mostly due to the fact that chimneys are constantly bombarded by the elements. Resting above the roofline virtually defenseless, chimneys do not have any roof or gutter system to divert water away from them as on the main part of your brick building.

A simple hairline crack in your chimney capstone, if neglected, can cause serious damage. Water penetration through a failed cap can cause the top courses of your chimney to disintegrate to the point where masonry repair is mandatory. When the majority of the brick on a chimney are spalling, flaking, cracking, displacing or even missing it is time to repair it with new masonry units. From mobilization to job clean up and all masonry repairs in between, contact Arrow Masonry.

Caulking

Caulking is one of Arrow Masonry’s value added services as it uses the rigging already in place for our core tuckpointing and masonry restoration procedures. It is also another preventative maintenance device for thwarting leaks. An open caulk joint can cause the same amount of damage as a void within a mortar joint can, by allowing unwelcome water into your buildings.

Arrow Masonry implements a variety of sealant products depending on job specifications. Polyurethane, silicone, and butyl rubber caulk are commonly used to form a watertight seal to all types of perimeter, control and expansion joints.

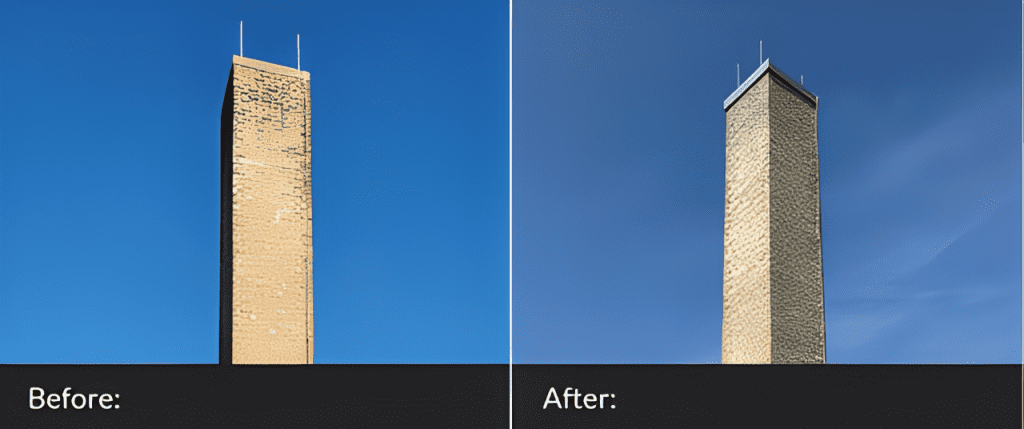

Power Washing

In addition to tuckpointing and masonry repair, Arrow Masonry also provides cleaning services for brick and stone. Power Washing is a relatively safe and cost effective method of furnishing your masonry building with a fresh new look. It is usually requested on older buildings where heavy pollution and traffic fumes have left their mark over the years.

Atmospheric dirt, carbon, mold and algae are all common deposits defacing brick surfaces. Chemicals, with the aid of a pressure washer, can work wonders to uncover the original look of your brick. The chemical is sprayed on to the masonry or stone surface then power rinsed off. Stubborn deposits are treated with a waterblasting method which incorporates both water and silica sand. Arrow Masonry pays special attention to preparing the worksite prior to any cleaning process to insure protection of exposed windows, doors, and landscaping.

Waterproofing

Waterproofing is a common preventative maintenance service that can minimize your masonry’s exposure to water damage. Just as tuckpointing will safeguard your mortar, waterproofing will shield your masonry from wind driven and saturating rains.

Likely candidates for waterproofing include smooth/splitface concrete block, limestone, renaissance stone, single wythe brick veneer walls, and sandblasted/waterblasted common brick as they are all particularly porous. Arrow Masonry also recommends sealing all types of masonry after any sort of rebuilding process is completed in order to sustain the new masonry work.

A standard Rilem Tube test is used by Arrow Masonry to determine water intrusion resistance and deflection. Once the saturation level is known, Arrow Masonry can predict which type of waterproofing material would be most effective on the masonry facade in question. Arrow Masonry utilizes two types of waterproofing agents: siloxane clearcoat and elastomeric colorcoat. Both products bond chemically to the substrate of the brick, block or stone and allow them to breathe. Siloxane agents are rolled or sprayed onto the masonry and do not change the appearance of the façade at all. Typically, clearcoat agents are applied to brick and stone surfaces. Elastomeric sealants are decorative coatings that are hand brushed on to the masonry and come in a variety of colors. Due to the porosity of concrete block, the elastomeric sealants are the best option for splitface and smooth block surfaces. Water can penetrate straight through the block allowing moisture/condensation to form on the interior of the block, in between the studs, insulation and drywall. If not addressed, mold and other toxic spores can form between your walls creating a health risk to you and your family. Once the elastomeric paint is applied it locks out moisture and prevents drafts. Arrow Masonry’s waterproofing applications are for above grade vertical surfaces exclusively. Waterproofing agents do require re-applications every so often as the products breakdown over time.